12.4.2024

Types of materials suitable for pneumatic conveying

Understanding Pneumatic Conveying Systems

Pneumatic conveying systems are integral to numerous industries, providing a reliable method for transporting bulk materials through pressurized air streams. These systems are favored for their efficiency, safety, and the ability to move materials through complex routes without the need for manual handling. At Kopar, we specialize in designing pneumatic conveying solutions that cater to a wide range of materials, ensuring that each system is tailored to meet the specific needs of our clients.

The versatility of pneumatic conveyors means they can handle a variety of materials, from fine powders to larger granules. The key to maximizing the efficiency of these systems lies in understanding the properties of the materials being conveyed. Factors such as particle size, shape, density, and abrasiveness play a crucial role in determining the most suitable conveying method, whether it be dilute phase, dense phase, or a customized solution.

Many years ago we realised that in order to understand how specific materials behave while being handled: be it crushing, feeding or transporting, they need to be tested. Therefore we built up our own testing facility, a pilot plant, which we are currently modernising and expanding so that we can even better cater to the needs of always changing industries.

Conveying Bulk Powders

Bulk powders are a common category of materials transported through pneumatic conveying systems. These fine, particulate substances require careful handling to prevent issues such as segregation or degradation. Kopar's advanced systems are engineered to maintain the integrity of powders like ash, metal concentrates and various chemicals throughout the conveying process. By controlling factors such as air velocity and pressure, we ensure that powders are delivered to their destination without compromising quality.

When it comes to bulk powders, it's essential to consider the potential for dust generation and the associated risks. Our pneumatic conveyors are designed with dust management in mind, incorporating features that minimize airborne particles and enhance the safety of the working environment. This attention to detail not only protects the health of workers but also helps maintain compliance with industry regulations.

Handling Granular Solids

Granular solids, with their larger and more irregular particle sizes, present a different set of challenges for pneumatic conveying. Materials such as grains, pellets, and certain types of minerals require systems that can accommodate their unique physical characteristics. Kopar's expertise in this area ensures that our conveyors are capable of moving granular solids efficiently, reducing the risk of blockages or excessive wear on the system components.

The durability of the conveying system is particularly important when dealing with abrasive granular materials. Kopar's conveyors are constructed using high-quality materials and components that are resistant to wear, extending the lifespan of the system and minimizing maintenance requirements. This robust design philosophy ensures that our clients receive a reliable and cost-effective solution for their granular material handling needs.

Transporting Fragile and Delicate Materials

Certain applications call for the gentle handling of fragile or delicate materials to prevent breakage or degradation. Pneumatic conveying systems can be fine-tuned to transport items such as pharmaceutical substances, food products, or other sensitive materials with the utmost care. Kopar's conveying solutions are customizable to provide the right balance of air flow and pressure to move these materials without causing damage.

The design of the system, including the pipeline layout and the choice of conveying phase, is critical when handling fragile materials. Our engineers take into account the specific requirements of each material, ensuring that the system is not only efficient but also preserves the quality and integrity of the products being conveyed. This level of customization is what sets Kopar apart in the industry.

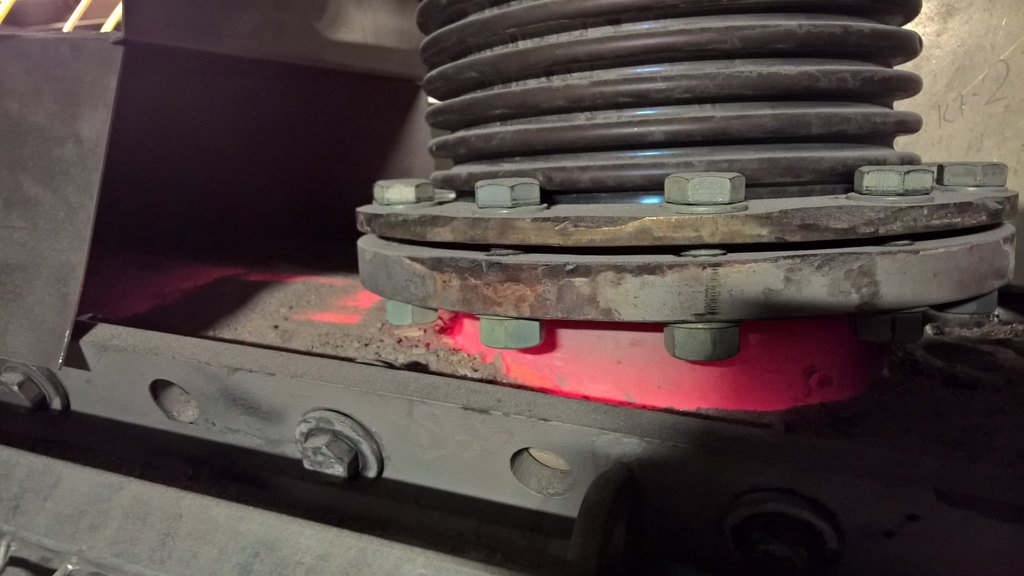

Conveying High-Temperature Materials

In industries where materials are processed at high temperatures, such as smelters and other metal manufacturing, conveying systems must be able to withstand extreme conditions. Kopar's pneumatic conveyors are engineered to handle high-temperature materials safely and effectively. By using specialized materials and construction techniques, we ensure that our systems can operate under these demanding circumstances without compromising performance.

The ability to maintain material flow while preventing heat transfer to the surrounding environment is a key consideration in the design of high-temperature conveying systems. Kopar's solutions incorporate insulation and cooling features as needed to protect both the material and the system itself. This attention to detail ensures that even the most challenging high-temperature applications can be managed with confidence.

Adapting to Moist or Sticky Materials

Moist or sticky materials can pose significant challenges for pneumatic conveying due to their tendency to clump or adhere to the sides of the conveying lines. Kopar's systems are designed with features that diminish material buildup, ensuring smoother and more continuous flow. By selecting the appropriate lining materials and implementing strategic system layouts, we help our clients overcome the difficulties associated with conveying these types of substances.

In addition to physical design considerations, the operational parameters of the pneumatic conveying system, such as air humidity and temperature, are carefully controlled to mitigate the effects of moisture on material flow. We offer our expertise for solving the most problematic material handling issues, but moist or sticky materials are often better conveyed by other means that pneumatic conveying.