Dome valve, also known as a cupola valve, is a specific type of valve widely used in industrial applications. It is designed to efficiently control the flow of materials in various processes, most typically in pneumatic conveying. Dome valves are an essential part of systems where precise and reliable material control is required.

The dome valve is particularly useful in applications where material flow is continuous and where precise control is needed. The unique structure of this valve allows it to be used in demanding conditions, making it an ideal choice for industrial operators seeking reliable solutions for material handling.

Although the dome valve may appear simple, its role in optimising industrial processes is significant. In this article, we will explore in more detail why dome valves are so important and how they function as part of a broader material handling system.

Why are dome valves used?

The use of dome valves is popular for many reasons, including their reliability and ease of use. One of the most significant advantages is their ability to handle large amounts of material without significant maintenance needs. This makes dome valves an ideal choice in environments where downtime can cause significant costs or disruptions to the production process.

Another major advantage is their simple yet effective design, which allows for easy installation and minimal maintenance needs. Dome valves perform well in various environments and applications, making them versatile and cost-effective solutions for the industry.

The reliability of dome valves is also based on their durability and ability to operate in demanding conditions. They are designed to withstand high pressures and temperatures, making them excellent choices for industrial applications where conditions can be challenging.

How does a dome valve work?

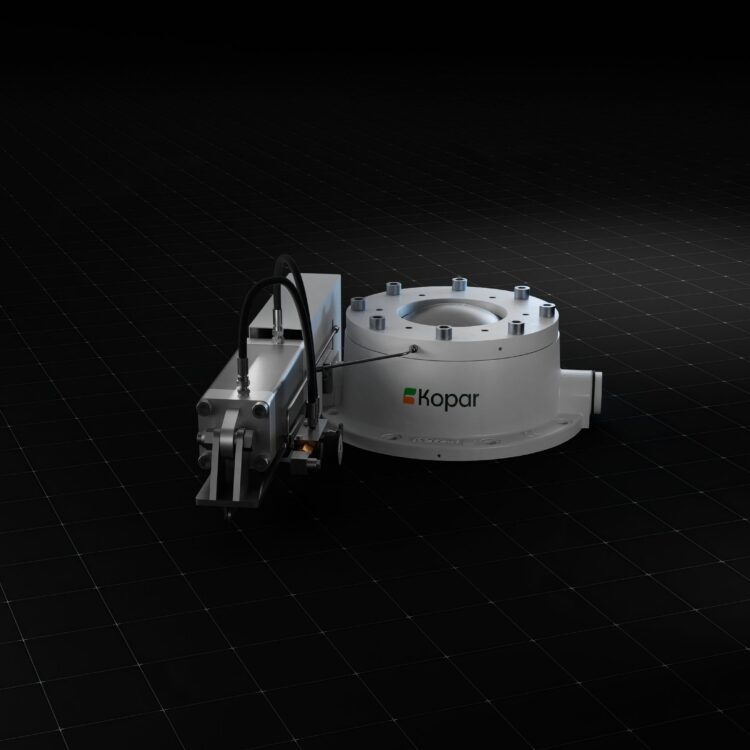

The operation of a Kopar dome valve is based on its unique design, which allows for efficient material flow. The dome of the valve opens up completely away from the material flow hence minimising the wear of the dome.

A dome valve operates by opening and closing the material flow channel, allowing it to precisely control the movement of material in the system. Kopar dome valve is a pressure tight and dust proof valve that seals the system perfectly making sure there is no contamination of the transported material nor the surrounding environment.

Compared to other types of valves, such as ball valves and butterfly valves, the advantage of a dome valve is its tightness. This makes it particularly useful in industrial processes where either material, environment or both need to be protected of contamination.

What are the advantages of a dome valve?

The most significant advantages of a dome valve are its durability and tightness, which make it an excellent choice for demanding industrial applications. Its ability to withstand high pressures and temperatures without significant wear is one of its greatest advantages.

The dome valve remains a popular choice for many industrial sectors due to the performance and reliability it offers. The benefits of its use often outweigh any potential drawbacks, especially when it is part of a well-designed system.

In which industries are dome valves used?

Dome valves are widely used in various industries, such as the chemical industry and energy industry, where the control of material flows is critical. They are particularly useful in applications where precise and reliable material control is needed.

In the chemical industry, dome valves help manage the flow of chemicals and other materials, which is essential for process efficiency and safety. In the energy industry, they are often used in pneumatic conveying systems of fly ash or bottom ash.

Additionally, dome valves can be used in other industrial sectors, such as mining and metal industries, where bulk material handling is a central part of the production process. Various sort of dry dusts and powders are easily transported pneumatically and in those pneumatic conveying systems dome valves are essential. Their versatility and durability make them an ideal choice for many different applications.

How is the installation and maintenance of a dome valve carried out?

The installation and maintenance of a dome valve are key factors in maintaining its long-term performance and efficiency. The installation process must ensure that the valve is correctly aligned and secured so that it can operate optimally.

Maintenance is also an important part of the upkeep of a dome valve. Regular inspections and maintenance procedures can help detect potential problems early and prevent the occurrence of major damage. This may include inspecting and replacing seals as necessary, as well as cleaning and lubricating the valve.

Proper installation and maintenance can significantly extend the life of a dome valve and ensure that it functions effectively as part of a wider material handling system. This ensures that production processes can continue without significant interruptions or disruptions.

You have a challenge that needs solving?

Let us help! Contact us for more information about our products and services.