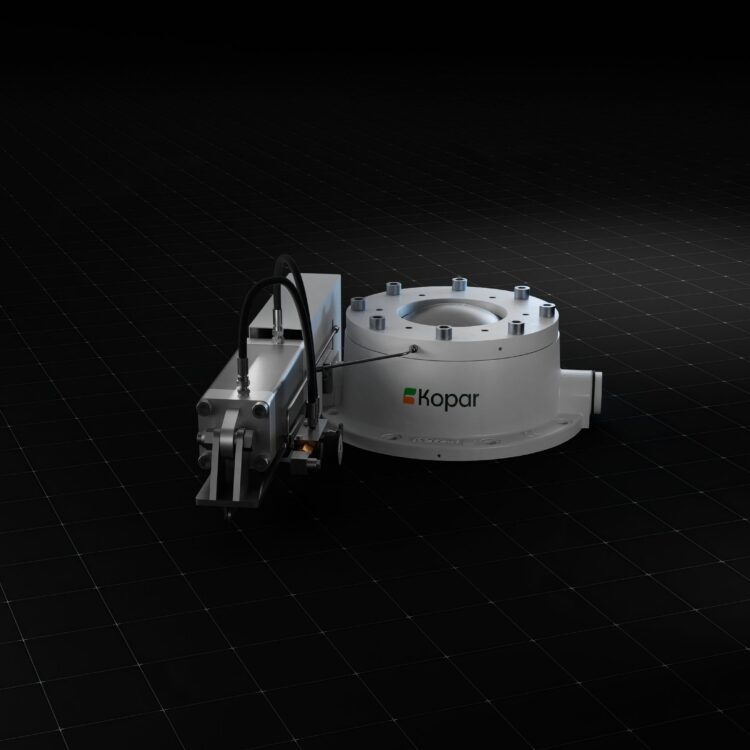

Pneumatic Conveying / dome valves

Dome valves - Designed to last

When the valve needs to be dust-proof, resistant to high tear and wear, withstand high pressures or hot conditions then the ideal solution is the Kopar dome valve.

Kopar dome valves are most typically used as feeding valves in pneumatic conveying. They are completely dust-proof, so even highly abrasive materials such as sand, cement, ash, concentrates and mineral powders can be conveyed with high capacity without the fear of dust flying around.

Designed to withstand 10 bar pressures as well as high wear and tear Kopar dome valves are made to last. Even hot conditions or ATEX environments are no problem for this robust valve.

Well over 1000 manufactured dome valves are already feeding material around the world.

The valuable customer feedback and collected experiences on behaviour of various bulk materials over the past decades have enabled us to further develop the product and tune the technical details of it even more.

Let us make your material flow better too!

Experience the versatility of Kopar dome valves

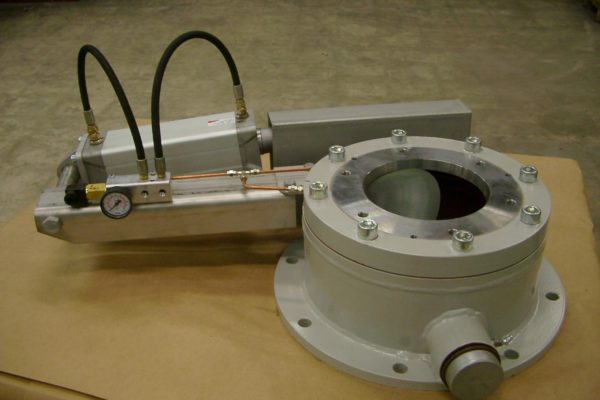

Kopar dome valves are engineered for various industrial applications, known for their simple structure and easy integration. With centralized air and electricity inputs, installation is streamlined, ensuring seamless integration into your systems.

Each valve features a quickly replaceable inflatable seal, reducing downtime and maintenance costs. The full-bore design minimizes wear by allowing the valve cap to open completely away from the material flow, thus extending the valve's lifespan.

The Kopar dome valve is available in three standard sizes (K100T, K200T, K300T), making it suitable for pipeline adapters ranging from DN65 to DN250. Large size dome valves up to DN800 are available at request as are pipeline adapters. Please inquire!

For potentially explosive atmospheres requiring strict compliance, we offer an ATEX20 certified version, ensuring safety and adherence to industry standards.

You can configure the suitable dome valve for your specific needs with our configurator. Check it out here!

Watch the video in Youtube

Designed to perform under the most demanding conditions or in applications requiring ultimate tightness, our valves offer exceptional reliability and cost efficiency.

Explore the capabilities of the Kopar dome valve, also known as Kopar Cupola Valve through our detailed video and see why it is the choice for businesses seeking reliable, long-lasting solutions.

Typical features of Kopar dome valves:

Pressure (bar)

max. 10

Operational temperature (°C)

0... +250

Max. operating temperature with cooling (°C)

+500

Keep you facility running

Technical specifications

Probably the most typical solution using a dome valve consists of an upper buffer bin (optional), a dome valve, a pressure vessel (i.e. the pneumatic conveyor), and a control unit. Through the open valve the material flows from buffer bin to the pneumatic conveyor (pressure vessel), and when it is filled, the dome valve closes and conveying sequence starts until the vessel is empty.

The dome valve body is made of carbon steel or acid-proof stainless steel.

Standard sizes, meaning the inlet size (DN):

K100T, K200T, K300T

Fitted with adapters from DN65 to DN250 pipelines.

Other size dome valves and pipeline fitters available on request!

Solution that assures high availability

Kopar dome valves are highly durable, but in case of a failure or an everyday need for servicing, the valve can be changed within an hour, and your facility is up and running again. With our solutions, there is no need for significant scale shutdowns.

Changing the inflatable seal on a dome valve is very straight forward work, see the video below on how simple task it is!

Kopar dome valves can also be retrofitted to current systems. They are easily installed and connected with existing automation systems. They are at best in demanding applications where tightness is essential and handled bulk materials abrasively.

One of the major advantages of a dome valve is that it opens up completely in the material flow and therefore wearing is moderate.

Servicing dome valves

Servicing a Kopar dome valve is very easy. Changing the inflatable seal is a straight forward procedure. See for yourself on the video!

Dome valves are at their best when you use them with our other solutions. Read more about our pneumatic conveyors and pipeline components.

We sometimes call our dome valves also as cupola valves. It is the exact same product, just a different name!

Watch the video in Youtube

Get a 3D model and see how does a

Kopar dome valve fit your plans

You have a challenge that needs solving?

Let us help! Contact us for more information about our products and services.