Tailormade forged conveyor chains

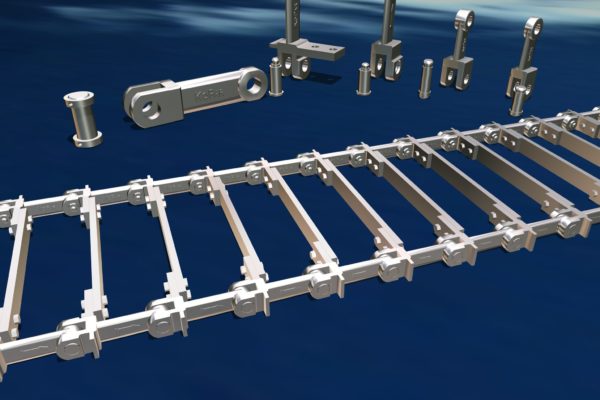

Forged conveyor chains are made for demanding applications. Kopar-drag chains withstand hot and abrasive conditions ensuring flawless, continuous conveying. Kopar-chains are Made in Finland.

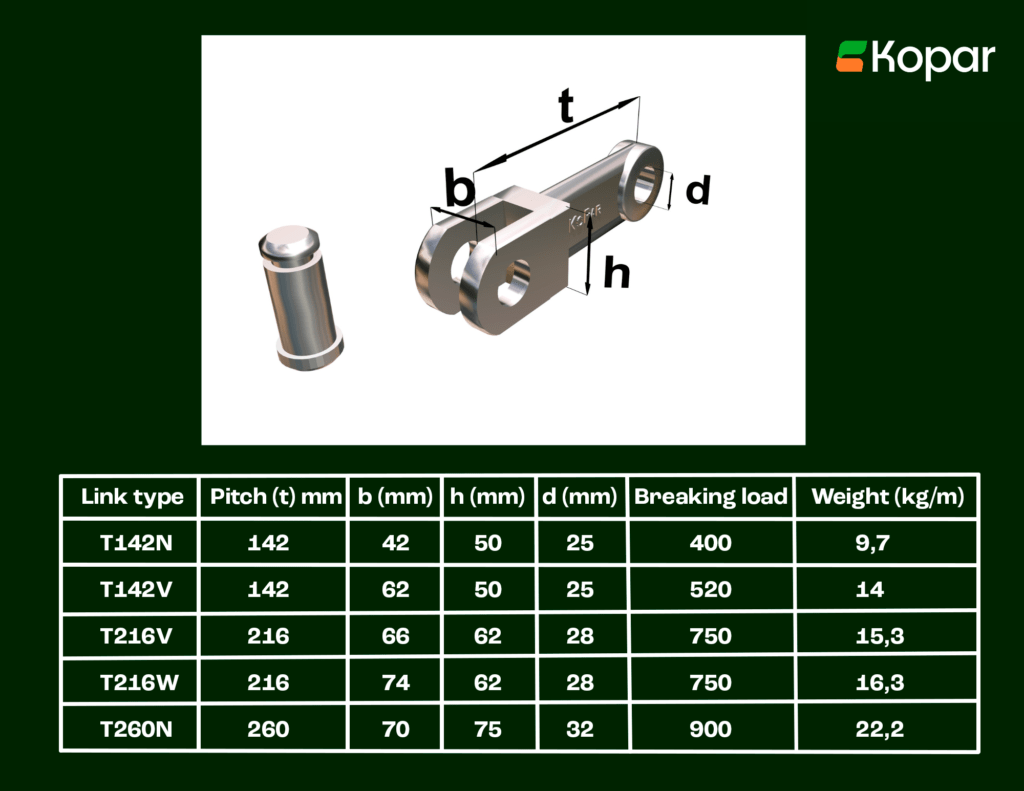

Our selection includes all standard size forged conveyor chain links from 142mm to 260mm, manufactured most typically of boron steel.

We have delivered drag chains to extreme operating conditions, for example to smelters and other metal refineries, for over 50 years. We can promise that our chains truly stand the test of time and continuous use at your facility.

Proven high heat resistance and outstanding breaking load are guaranteed by careful designing and meticulous manufacturing.

We always recommend to change the sprockets together with the conveyor chain to make sure your drag chain conveyors keep the process running. In addition to the parts we can also take care of the actual change - just get in touch with us and we'll get it sorted!

Try our Chain Configurator now!

Let our Chain Configurator calculate the perfect chain setup for your needs and take you a step towards achieving smoother operations and longer-lasting chains.

Guaranteed for heavy-duty operation

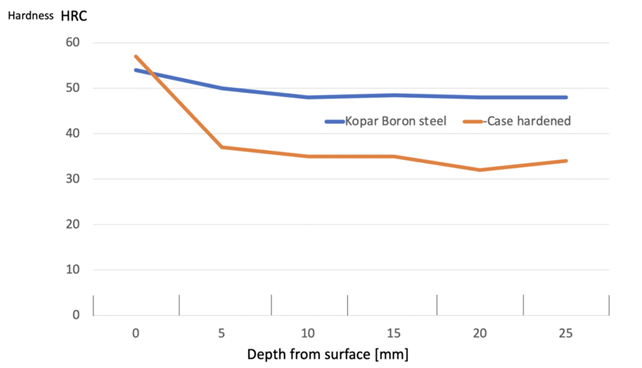

One reason for the superior performance of Kopar forged conveyor chains is the special steel alloy with boron addition and the heat-treatment process that results in hardening throughout the link. Therefore Kopar conveyor chain maintains its properties even under high temperatures and heavy abrasion withstanding wearing better than traditional forged conveyor chains made of case-hardened steels.

Designed to last in the harshest of conditions

Selection and justification of appropriate chain material

Kopar forged conveyor chains not only guarantee that the chain meets the demands set by your process and conditions, but they also guarantee the lowest operational costs (OPEX) and the lowest total costs of ownership.

The most widely used chain link material in industrial applications worldwide is case-hardened manganese steel (20MnCr5 / EN 1.7147). Typically the purchasing price of manganese chain is lower than that of boron steel. However in bulk material handling processes that are extremely prone to wear it is wise to also consider the lifetime of the chain a the replacement intervals. Although boron steel chains are slightly more expensive to purchase, approximately 50% more than the traditional manganese chains, the lifetime is significantly longer! Double, triple and even quadruple lifetimes mean huge savings in both money and time resources.

Based on the previous we strongly favour the tempering steel with boron addition i.e. boron steel (27MnCrB5 / EN 1.7182) due to its multiple lifetimes and, thus, the clear benefits it brings to users of conveyor chains.

For special cases we supply chains made of heat resistance steel (1.4713) for those applications which continuously operate at temperatures up to 700 °C and for harsh chemical conditions stainless steel (AISI 420 / EN 1.4034) is used.

Continuous maintenance

Anticipation is the key to keep your drag chain conveyors up and running without unplanned stops.

We have developed a practical tool to measure elongation easily and as often as you want. This straightforward procedure guarantees the maximum lifetime of the chain and minimizes the risk of breakage and unplanned corrective maintenance.

We recommend changing the chains when the elongation has reached 2,8%. The sprockets are to be replaced at the same time the chain is renewed to ensure optimal operation of your process.

Looking for a replacement?

Each material handling application is unique and requires specific conveyor chain to perform its conveying task in an optimal way.

All Kopar conveyor chains are assembled to order. The type of the link as well as the amount and location of flights is decided based on the characteristics of transported material.

In order to provide a quote, we require the following information:

- chain type in use

- width of the chain or width of the conveyor

- type and shape of flights

- pitch of flights

Of highest quality

We have been awarded the Key Flag symbol that proves Finnish quality, competence, and know-how. Companies worldwide use our key ticketing product, a conveying chain.

Before shipping the chains to run our clients' facilities worldwide, the chains undergo a rigorous QA process. We continuously improve our designs to ensure the most durable solutions that keep things running smoothly and your expenses low.

You have a challenge that needs solving?

Let us help! Contact us for more information about our products and services.