What is a dome valve?

A dome valve, also known as a cupola valve, is a specialized type of valve designed for efficient material transportation and handling in industrial applications. Its unique structure and operation make it an excellent choice, especially when precise flow control and durability are required. The operation of a dome valve is based on its ability to open and close efficiently, allowing smooth material flow from a pressure vessel or pneumatic conveyor without disruptions.

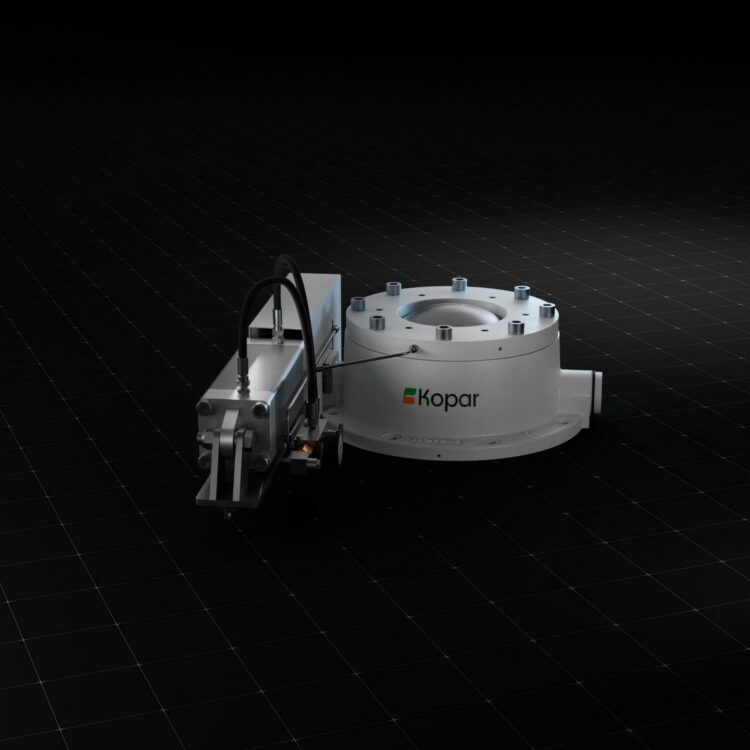

The design of the dome valve emphasizes its simplicity and reliability. The valve structure consists of an upper part that opens and closes to regulate material flow. This design allows the valve to be used in various industrial environments where a durable solution is needed. The synonymy of the dome valve with the cupola valve is due to their similar operation and structure, making them interchangeable.

The use of a dome valve is particularly beneficial in situations where material transport and handling require precision and durability. Its simple yet effective design ensures reliable operation, which in turn allows the optimization of industrial processes and the reduction of environmental impacts.

How does a Kopar dome valve differ from other valves?

A Kopar dome valve differs from other valves, particularly concerning its design and operating mechanism. Unlike traditional dome valves that may rely on complex mechanisms, the Kopar dome valve is characterized by simplicity and durability. Its structure contains fewer moving parts, which reduces wear and the need for maintenance. Fast maintenance and servicing has been a key feature in design of the Kopar dome valve allowing for example the change of the dome alone without a need to dismantle the complete valve with pedestal.

Compared to other types of valves, such as butterfly valves or ball valves, the advantage of the dome valve is its ability to remain dust-proof and pressure-proof. This makes it particularly suitable for use in industrial applications where dusty bulk materials are handled and both the handled material and the surrounding environment need to be protected from contamination.

The operation of the dome valve is pneumatic, which allows the valve to open and close quickly and efficiently. This operation ensures that material flows smoothly without interruptions, which is crucial in many industrial processes.

What is a dome valve used for?

The dome valve is widely used in industrial applications where reliable material handling is required. One of its most significant applications is the pneumatic conveying of bulk materials such as chemical compounds, process dusts, filter dusts, ashes, sand etc. The valve's ability to handle large amounts of material makes it an ideal solution for such processes.

Another common application for the dome valve is in industries, where precise flow control and material mixing are required. The valve's durable construction and material choices, such as acid-resistant stainless steel, make it suitable for handling harsh chemicals.

Advantages of a dome valve

The use of a dome valve has many advantages, particularly its durability and efficiency in industrial applications. Its simple design reduces the need for maintenance and extends its lifetime, making it a cost-effective solution. Being a full bore valve meaning that it opens up completely away from the material flow, makes Kopar dome valve especially good choice as this further reduces the servicing need and extends the life of the valve. In addition, its ability to handle large amounts of material without the risk of clogging improves the smoothness of production processes.

Maintenance and upkeep of a dome valve

Regular maintenance and upkeep of a dome valve are essential to ensure its long service life and reliable operation. The simple design of the valve reduces the need for maintenance, but regular inspections help detect potential issues early.

Maintenance tasks include cleaning and lubricating the valve, which prevents material build-up and reduces friction. Additionally, inspecting and, if necessary, replacing the valve seals is important to ensure the valve's tightness and prevent leaks.

It is also recommended to monitor the valve's operation and performance regularly to detect any deviations in time. This helps optimize the use of the valve and reduces downtime in industrial production.

You have a challenge that needs solving?

Let us help! Contact us for more information about our products and services.