Classification & Storage / Crushers

When conveyed material needs resizing

Kopar crushers typically act as primary crushers for metallurgical lumps from waste heat boilers, slags, and dusts. They can tolerate a continuous temperature of 300 °C.

Kopar rotor and roll crushers are suitable for crushing cloddy or lumpy materials. Waste heat boiler slag, dust lumps, and bottom ash are typical materials that need resizing in the process.

Once the material is smaller and finer, it is more easily transported with conveyors. Especially pneumatic conveying requires small-sized particles in order to operate smoothly.

Considering the dew point of handled material is crucial, and therefore, equipment must often be insulated. Our experience has shown that it is advantageous to use easily removable insulation panels, which are pre-installed already at the factory.

Our crushers are designed to last. A new rotor design guarantees a longer lifespan. The innovative design also facilitates easy maintenance, minimizing production halts when necessary.

You can easily integrate our crushing solutions with our pneumatic or mechanical conveying solutions to maximize your facility's efficiency and productivity.

Suitable usage cases for crushers

Metallurgical Industry:

Waste Heat Boiler lumps, dust and slag.

Energy & Power Industry:

Multiple usages for several different materials - bottom ash, brown coal, coal, lignite, limestone.

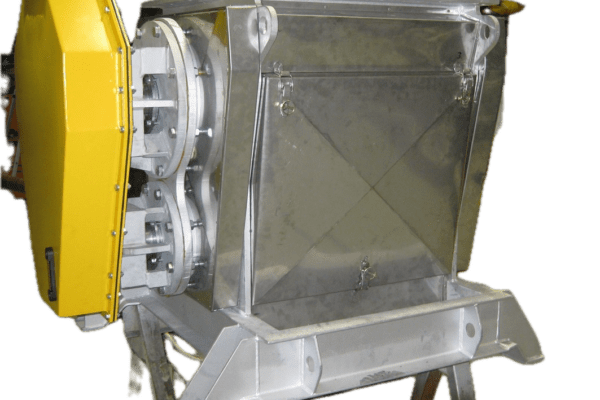

Typical features of Kopar Rotor Crusher

Capacity (t/h)

0-50

Inlet particle size (mm)

300 x 300

Outlet particle size (mm)

12-30

All models have the following options: cooling, heating, insulation.

A new feature with hydraulically openable blades to clear jams.

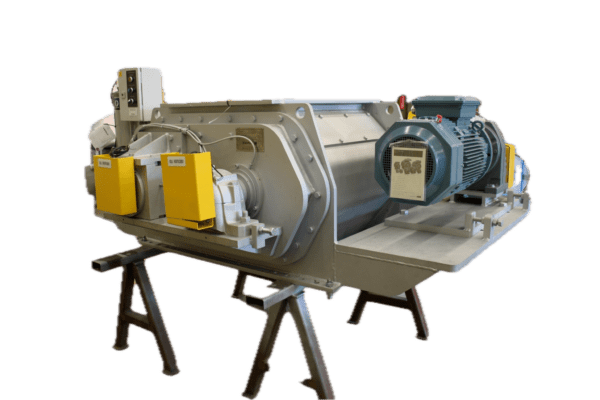

Typical features of Kopar Roll Crusher

Capacity (t/h)

0-30

Inlet particle size (mm)

30 x 30

Outlet particle size (mm)

< 3

with an adjustable size distribution

All models have the following options: cooling, heating, insulation.

Different crusher for different materials

Combination of crushers for optimal results

A required crushing process may consist of one rotor crusher, a combination of two rotor crushers, a combination of one rotor and one roll crusher or one roll crusher.

Our rotor crushers are designed to process relatively coarse materials, with a maximum inlet size of around 300×300 mm. Typical crushing ratio in a single stage is five, but by combining stages the desired particle size at outlet can be achieved.

Rotor crushers for coarse materials

If this size range does not meet your specific needs, you have the flexibility to continue the process either with a finer-bladed rotor crusher or with a roll crusher, depending on the desired final particle size and capacity. The new rotor construction introduces a design that allows for easy blade replacement without requiring the replacement of the entire shaft. This new, modernised, construction also enables the use of materials with higher strength, significantly enhancing the overall durability of the crusher.

Roll crusher for fine materials

With our roll crusher, it is possible to meet the final size distribution down to 100 % < 3 mm, depending on the material and the capacity. It is adjustable for your customized needs.

There are plenty of options on combinations, just get in touch and let's figure out the most advantageous crushing solution for your process!

Test how Kopar Crushers fit your production plans by downloading a 3D model or build the crusher you need with our configurator

You have a challenge that needs solving?

Let us help! Contact us for more information about our products and services.