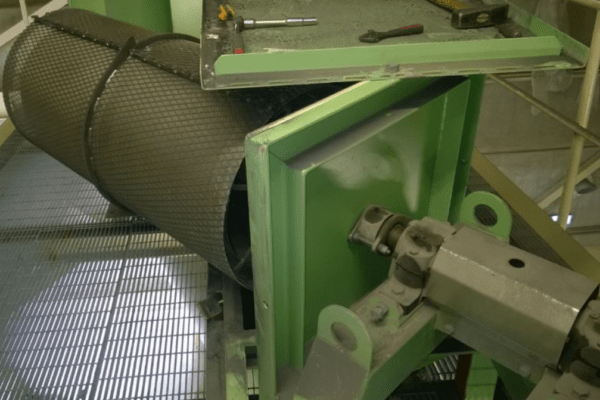

Classification & Storage / Drum Screens

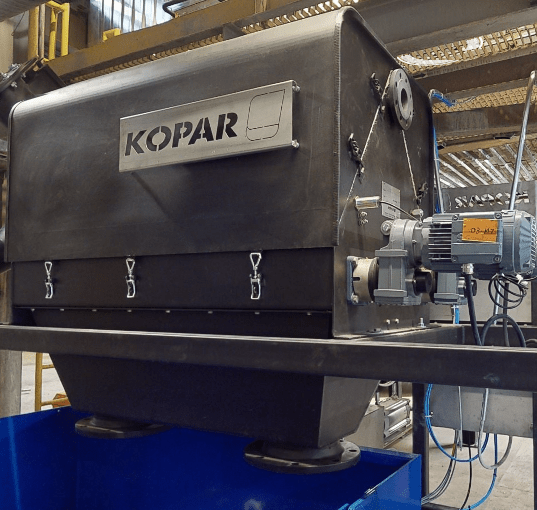

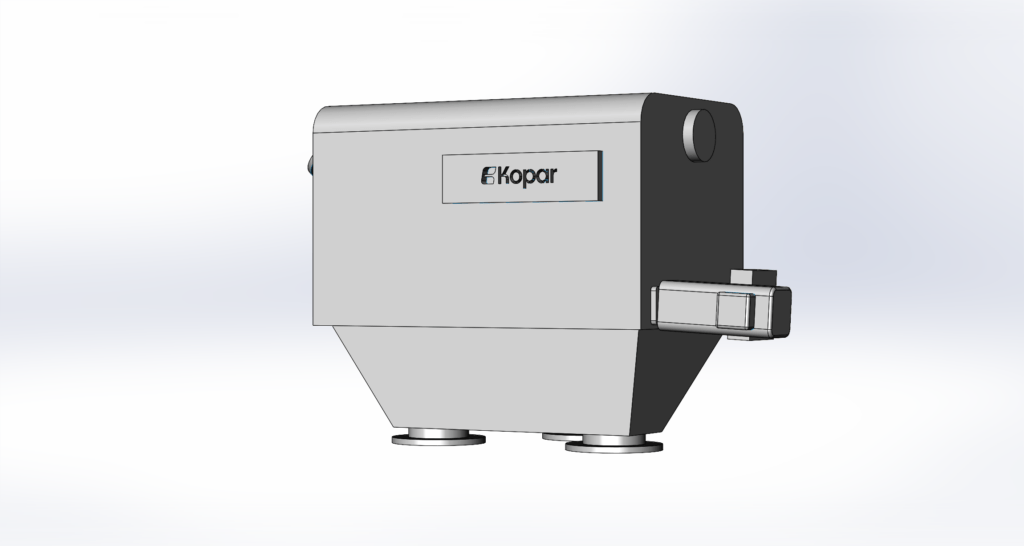

Drum Screens – Fine screening with low maintenance

Kopar drum screens are a compact solution for sorting materials and screening desired fraction sizes. They allow separating three material fractions at once. It makes recycling and the green transition one step easier.

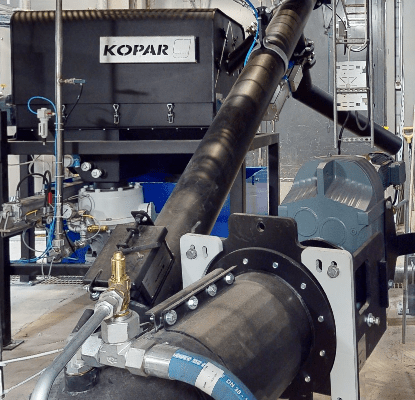

With the burning of solid fuels in boilers, a considerable amount of bottom ash is produced. This ash contains impurities, making the recovery of pure, ash-free sand challenging.

Our drum screens play a vital role in this process by efficiently separating sand from the bottom ash stream. It supports the green transition by enabling the recirculation of valuable sand back to the circular fluid bed boiler.

Drum screens are also applicable for fractioning various materials, e.g. metallurgical slags.

Suitable usage cases for our drum screens

You can use our drum screens for handling free-flowing materials in:

- Separation of ash and sand in power plants

- Screening of stored ash

- Fractioning of products like slags for further use

Typical features of Kopar drum screens are:

Capacity (t/h)

0,5–5

Fractions (mm)

<0,5

0,5 – 1,5

>1,5

High availability

Equal distribution of material

Kopar drum screens are an effective solution for your screening needs. With our drum screens, you can easily separate coarse material from fine material. As the material distributes equally onto the screening surface, it flows freely through the screen without any build-ups.

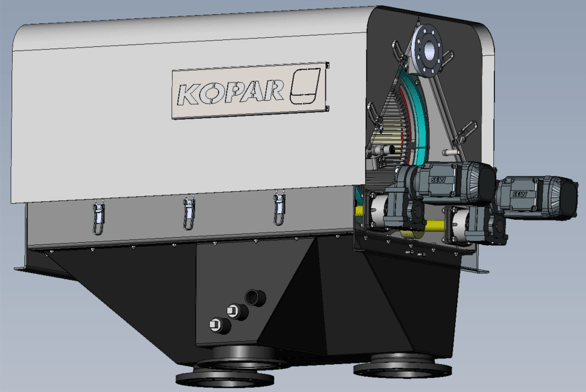

Unique design and structure

Our drum screens are a combination of mechanical and pneumatic cleaning with a unique screen drum dual-layer screening method, which makes them suitable for challenging conditions. Rotation of the drum keeps the material in constant move resulting in high efficiency and capacity.

In-built cleaning mechanism

All this can be achieved with very high availability as there are several automated cleaning systems comprising mechanical brushing, mechanical impact system and automated compressed air, or any combination of these. These cleaning installations keep the screen surface open, allowing a high utilization rate of the existing screen surface area.

Test how Kopar Drum Screens fit to your layout

You have a challenge that needs solving?

Let us help! Contact us for more information about our products and services.